“That’s the way we’ve always done it.”

That phrase might feel familiar. It also might be costing your organization more than you realize.

Most companies don’t suffer from a lack of process—they suffer from processes that are invisible, unchallenged, and stagnant. They rely on what once worked, assuming it still does. But in today’s fast-paced business climate, that assumption is dangerous.

In this article, we’ll show you the evolution of process design—from static and fragile to resilient and self-improving. And we’ll challenge you to choose one internal process this quarter and make it better.

Step 1 – The Black Box: The Illusion of Stability

Let’s start with the most common scenario: the black box process.

In science and engineering, a “black box” is something where inputs go in and outputs come out, but the internal workings are either unknown or inaccessible. Many business processes function exactly the same way.

They work—until they don’t. And when they fail, the root cause is hard to find because no one really knows what’s going on inside. Why?

- There’s no ongoing ownership

- No scheduled review or refresh

- No documented logic or improvement history

- And often, no one empowered to question it

Over time, these processes become tribal folklore: “That’s the way we’ve always done it.” But when the people who knew why leave, what’s left behind is brittle, outdated, and misaligned with how the business actually works.

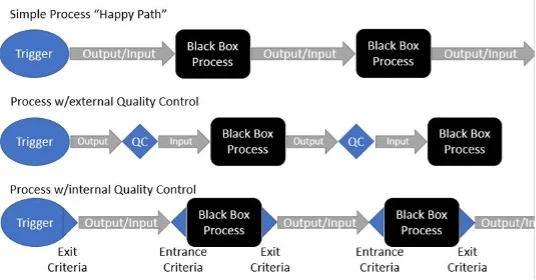

Step 2 – Add Checkpoints: Empowering Quality Control (QC)

To improve a black box, you have to first open it—and then add accountability.

This happens in two primary ways:

🔹 External QC

Review the output of one step before it becomes the input to the next. Think of it like a double-check at the handoff. Common in manufacturing and professional services.

🔹 Internal QC

Build the criteria right into the process:

- Entrance criteria: What must be true before we start?

- Exit criteria: What must be delivered or verified before we move on?

These checkpoints standardise outcomes and reduce risk. But more importantly, they create empowerment.

Many frontline team members don’t feel authorised to push back or enforce standards—they just do their job.

QC gives them a reason—and a responsibility—to protect the integrity of the process.

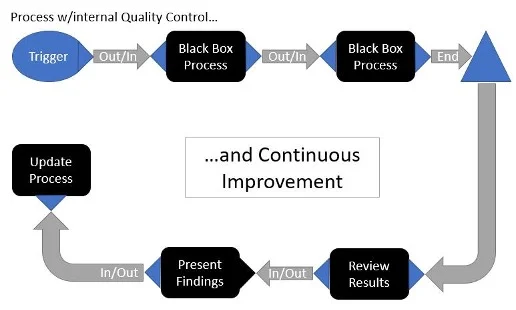

Step 3 – Continuous Improvement: A Process That Learns

This is where your process becomes more than just a list of steps—it becomes a living system.

In a mature process, the results of one cycle feed the next. This loop includes:

- Reviewing outcomes

- Presenting findings

- Updating the process

- Reinforcing improvements over time

When done right, this doesn’t add overhead—it creates acceleration:

- Faster onboarding

- Stronger training programs

- Smarter automation

- Less rework

- Higher confidence

Real-World Example: New Client Onboarding

Let’s look at how this plays out using a deceptively simple example: partner onboarding.

Initial Version (Black Box):

- Agreement signed

- Kickoff scheduled

- Client added to system

- Team assigned

It works… until a client gets forgotten, or critical data is missing, or the wrong team is assigned.

Enhanced with QC:

- External QC: Validate contract completeness, review scope with sales

- Internal QC: Required checklist before system setup; approval before kickoff

Upgraded with Continuous Improvement:

- Add welcome email template

- Include IT documentation handoff

- Trigger Quarterly Business Review meeting prep

- Survey new clients to close the feedback loop

- Use results to improve internal process and automate future steps

Over time, what was once a checkbox becomes a predictable, scalable, and brand-defining experience.

Bonus Tip: Use the SATs to Design the Process

Before creating or fixing any process, apply the SATs framework from Article #3:

- Strategy: What is this process trying to achieve? What does success look like?

- Analysis: What are the options, risks, and best practices?

- Tactics: What steps are needed, and how will we review them?

Designing with SAT ensures your process isn’t just a list of tasks—it’s a plan with purpose.

Conclusion: From “That’s the Way We’ve Always Done It” to “This Gets Better Every Time”

Your business changes. So should your processes.

If your team is still running workflows that were designed five years ago by someone who no longer works there—without checkpoints, without documentation, without reflection—then it’s time to take a closer look.

Continuous Improvement isn’t a buzzword. It’s a cultural cornerstone.

And the easiest way to embed it into your culture… is to build it into your processes.

Start small. Choose one process. Add a checkpoint. Build a loop. Empower your team to improve it.

Then? Watch the quality of everything else start to rise.